Remote control for industrial robot

Topic outline

-

- Time: < 2h

- Language: English

- Access: Free

- Level: Intermediate

-

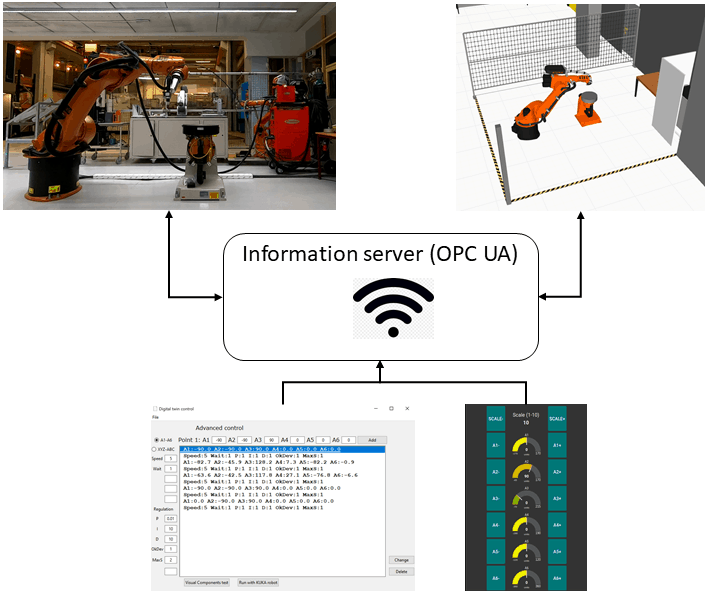

Each robot manufacturer usually has a different user interface and programming method. Systems with multiple robot controllers and machines can increase the difficulty of programming. However, having one control method for all the robots can significantly simplify the control and programming. This module showcases how an industrial information server can be used to unify the control/programming of robots using one simple control interface.

The module is based on the module “Rapid mapping of a production system in a virtual environment” and “Connecting virtual model with the physical model”. However, this module adds robot control and programming functionality. The module will guide user to setup a GUI with the industrial robot and to program the robot.

The main objective of the module is to show how multiple industrial robots can be controlled remotely through one centralized and simple GUI instead of the teach pendant.

The key learnings from this module are:- How to use an industrial information server (OPC UA) to control robots and other machines

- Examples of how to use the same GUI/HMI to control robots with the same user interface for different types of robots

The user will develop skills in:- The user will acquire knowledge on how to merge robots from different brands and to use them through one centralized control interface

- How to remotely be able to control and monitor multiple robots and machines

-

University/Research Institute/Students, Manufacturing SMEs, Developers

-

The user should be familiar with programming, industrial simulation software and industrial robot

-

Integrator version

-

Developer version: