Additive TiG Welding

Topic outline

-

- Time < 1h

- Language: English

- Access: Free

- Level: Intermediate

-

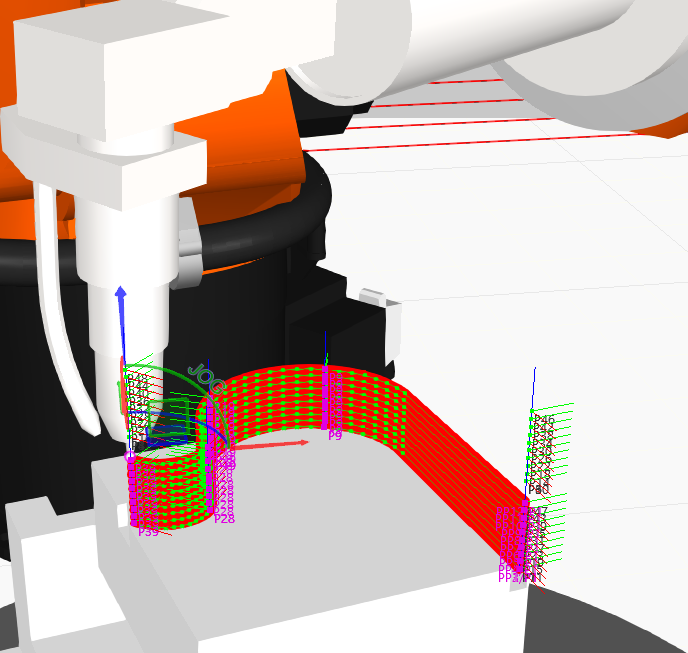

The module uses a KUKA robot to perform metal additive manufacturing of thin wall structures using TIG welding. It uses the simulation program Visual Components as a programming interface and allows for advanced programming functions/commands to be executed on the KUKA robot and rotary table.

These videos will showcase how you can use a standard industrial robot arm for 3D printing with robot welding. The videos will also show how you can use a simulation software to automatically generate programs for the physical robot.

The key learning from this module is:- Showcase how you can 3D print with robotic welder

The user will develop skills in:- 3D printing with welding robot

- Showcase how wire arc additive manufacturing works

-

University/Research Institute/Students, Manufacturing SMEs, Developers

-

The user should be familiar with:

- Simulation software in this case Visual Components

- Beneficial to have experience with the OPC UA server

- Some experience with robot control with an external computer

-

Integrator version