MTM Universal Analysis System (UAS)

Topic outline

-

Time: <1 h

Language: English

Access: Free

Level: Medium -

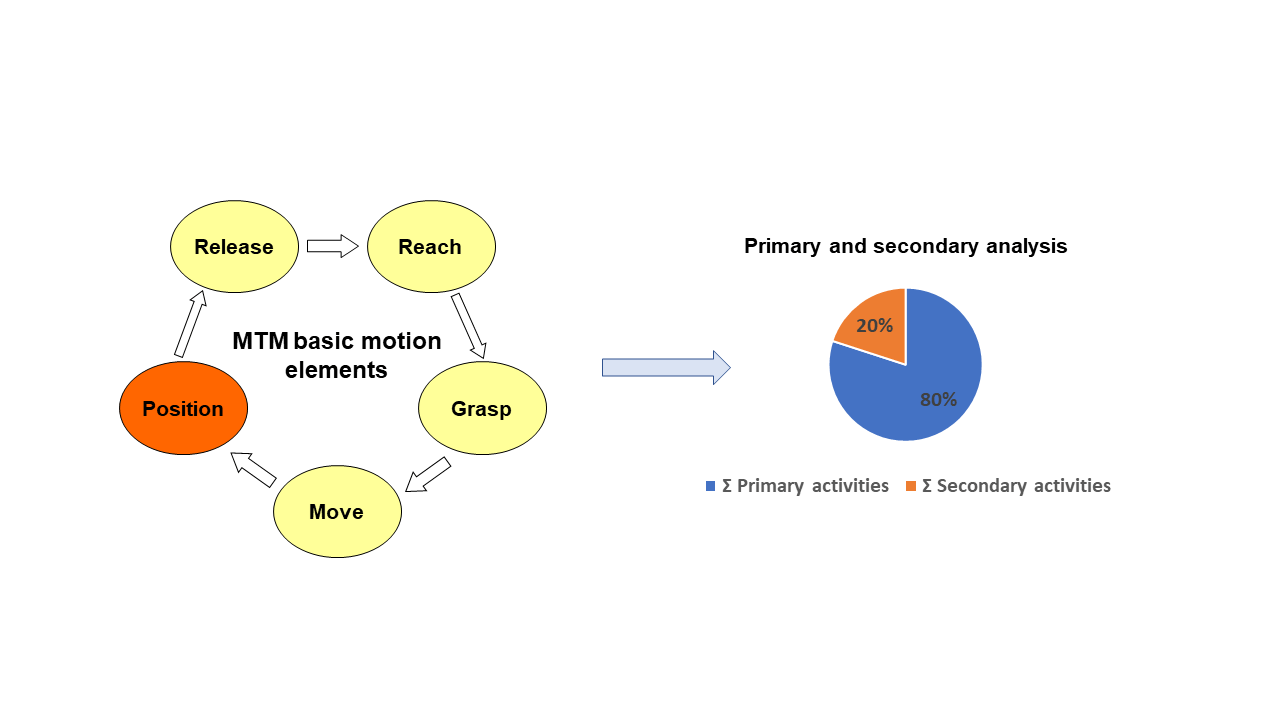

The American ergonomists Maynard, Schwab and Stegemerten developed under a consulting contract with Westinghouse Electric Corp. between 1940 and 1948 the basic data of the MTM process. In the 1960s, MTM was expanded or modified to the systems used today. MTM is a method in which manual processes are broken down into their basic movements. A known standard time value is assigned to each basic movement. This enables the optimal method to be determined as early as the planning phase.

Through the training for the MTM UAS module the participant will be informed that this tool is ideal to create work processes to achieve high benefit and to eliminate waste already in the planning phase. The participant learns that MTM finds its justification especially in the planning processes. To create an analysis only knowledge about thestructure of the work system as well as an idea of the planned work processes are necessary. It is not necessary to find an existing process or workplace for the application of the MTM method like it is required in contrast to the time recording by means of a stopwatch (REFA).The users will improve knowledge of ergonomics and economy during the planning phase of manual or hybrid workplaces. Taking into account the possibility of assignment, e.g. assembly tasks on humans and robots, without creating waiting times for humans. Participants will get an opportunity to develop competencies in knowledge of MTM-UAS as an objective time management toll. The competence for the general understanding in the area of ergonomic and thus economical manual and hybrid work system design will be developed.

-

Manufacturing SMEs; Technology Provider; System Integrators; End Users

-

The user should have basic skills in process planning processes and work preparation

-

Integrator version

-

Production Manager - Developer version: